3D Curved Panels & Assemblies

Manufactured in New Zealand using world leading adaptive mould technology

C U R V E W O R K S N Z

Intelligent reconfigurable

curved surfaces

Go from design to production in virtually the click of a button. Book your production space on our Adapa D100 adaptive mould machine at our purpose-built facility.

A B O U T O U R M A C H I N E

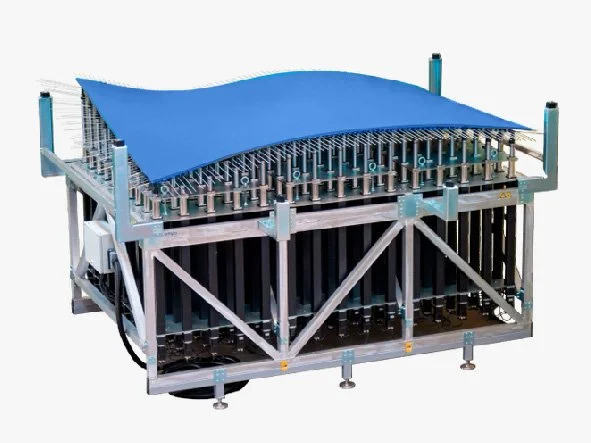

Adapa D100

Adaptive Mould

Ideal for Glass Fibre, Composites and Thermoplastics with double curved geometry.

We provide full support to suit your customized formwork solutions. Curveworks NZ can support you in design and manufacture of customised formwork solutions according to your requirements:

Full-service design & manufacture

Expert material supply information

-

400mm

-

3600mm L x 2160mm W x 1000mm H

-

280kg/m²

-

+/- 1.5mm

-

Rhino 3D CAD

A D A P T I V E M O U L D S

Advantages of computer aided manufacture.

-

One mould can take multiple shapes, and it can do so within minutes. This means that you have:

The possibility to fabricate different materials and designs with a single mould

No waiting time for tooling

Maximum flexibility for last minute changes and design iterations

-

The Adaptive Mould eliminates the need for manufacturing unique tooling for every panel as you have:

Minimal tooling costs

Reduced space requirements in your production setup

Shorter production time

-

The Adaptive Mould significantly reduces your potential waste of disposable moulds, as you have:

Less logistical costs due to no transportation or storage of disposable moulds

A more sustainable production and a smaller carbon footprint impact

Signicantly less waste to manage

-

The flexible properties of the Adaptive Mould allow for multi-stage forming, including a process such as the following:

Lay-up surface layer in flat stage

Adjust the mould into the curved shape

Release the panel by selectively lowering the actuators

-

The Adapa Tools software eliminates the need for manual measuring and support you to benefit from the advantage of:

Low mould surface tolerances

Guidance by accurate 3D laser

Guided positioning of inlays, brackets and fixtures

-

The Adaptive Mould is designed to handle surface temperatures up to 200°C and collaborate with several technologies:

Magnetic silicon sides and shuttering for panel edge precision

Top liners for patterns or inlays

Vacuum and infusion

Heating mats

Robotic lay-ups up or post processes

-

We can support you in design and manufacture of customised formwork solutions according to your request and your preference in manufacture and purchase. We support you by offering:

Full service design and manufacture on your request

Provide sub-supplier information for your purchase department

Deliver drawings and manufacture specification for you own manufacture

Key Features

-

1.

5 minutes from CAD

file to curved surface. -

2.

Laser projection

accuracy. -

3.

Tolerance to Aerospace standards with anticipated warp effect programming.

-

4.

Easy HMI touch

operation. -

5.

Multi material compatibility eg. composites, plywood, concrete etc.

Fabricating curved panels in